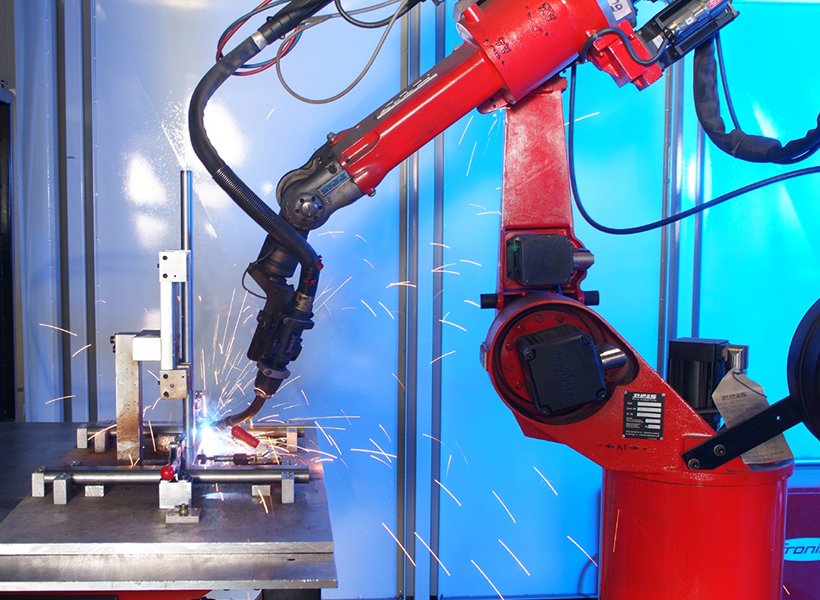

Metal Production

In the metal production aluminium profiles of high quality are cut with the greatest precision with the help of laser-controlled machines to fit our basic boards, before these are powdered with our in-house developed powder coating in standardised, yet also individual RAL colours. Additionally, welding work (for example for our stylish flip chards) is undertaken – on the one hand by a state-of-the-art welding robot, on the other also by hand to meet individual customer’s wishes. Furthermore, the metal production is equipped with folding benches, drills, and punch presses, which lets WEIGANG react flexibly to your requirements.

Plastics Production

With the help of machines in mint condition, WEIGANG can weld and reshape different plastics. This know-how is used to produce visualisation and planning accessories that supplement our classic shop floor boards and planning boards or office organisation utensils, like for example the Datoclip+series. Our resulting great product range and depth makes WEIGANG an ideal partner to fulfil your wishes through our holistic solutions. Here, too, things are on the one hand produced in series, on the other hand, custom-made products are realised, which barely constrains creativity and individual solutions.

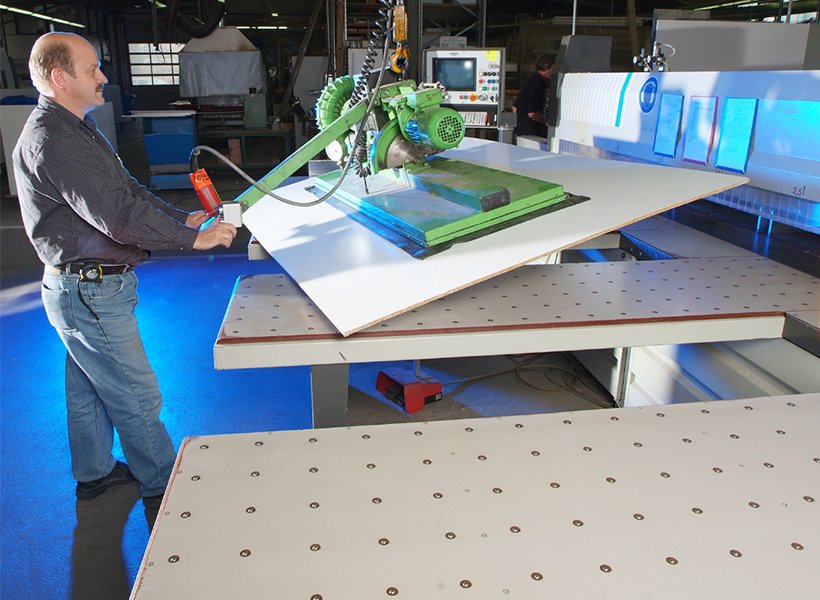

Wood Production

In the wood production WEIGANG can process the most diverse materials. High quality CNC-machines, coupled with our employees’ handiwork, precise down to the millimetre, and the decades of experience in the wood production area, make up the ideal basis to produce high quality products, no matter whether in series or custom made. Conference furniture, shop floor boards, manual planning boards or workshop planners, WEIGANG offers you virtually boundless opportunities to cover your needs and implement your plans.

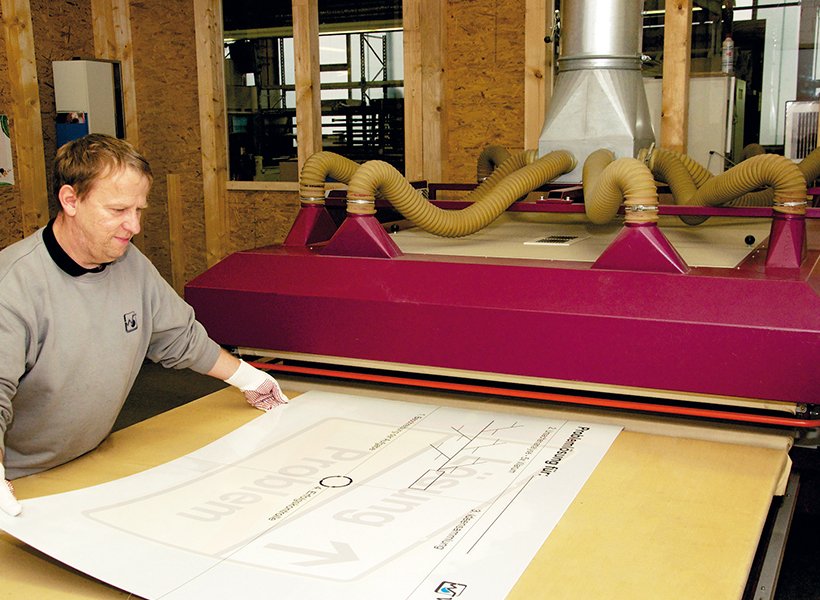

Paper Production

In the paper production, the fourth of the five production areas, printed products of all kinds are printed with sustainable materials made from recycled paper. Adding to our classical planning and organisation media, index cards, forms, and further accessories, for example for our Datoclip+-series, labelling elements for our basic boards, or plastic printed with our screen printing process, is created.

Equipment Manufacture

The equipment manufacture, the last of WEIGANG’s five production areas, makes up the final assembly of WEIGANG products. Here, all puzzle pieces are assembled by hand to make the final product. This is the reason for the high quality of our products: During the assembly, the products’ intactness is very carefully ensured. After the assembly, all products are thoroughly tested in strict quality controls, before they are packaged in sustainable materials in dispatch and shipped around the world.