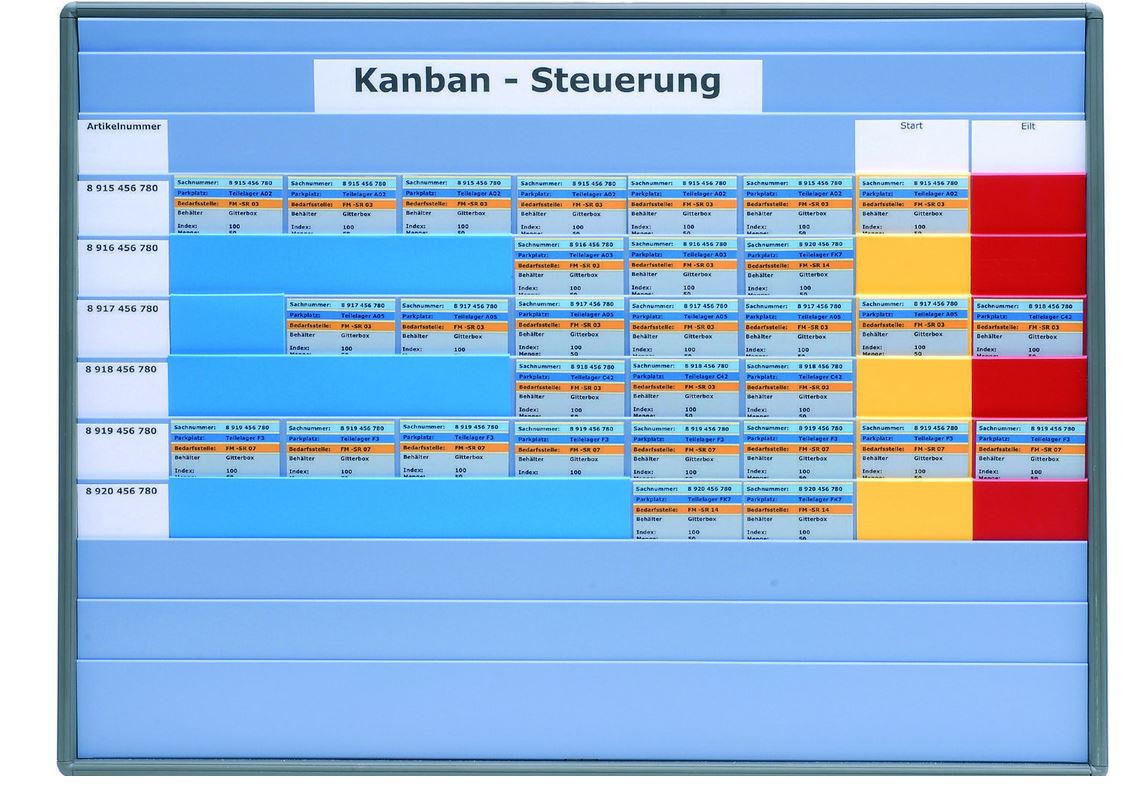

Kanban Tafel "Staffelsicht V"

- modular aufgebaut

- Erweiterung jederzeit möglich

- Zubehör seperat erhältlich

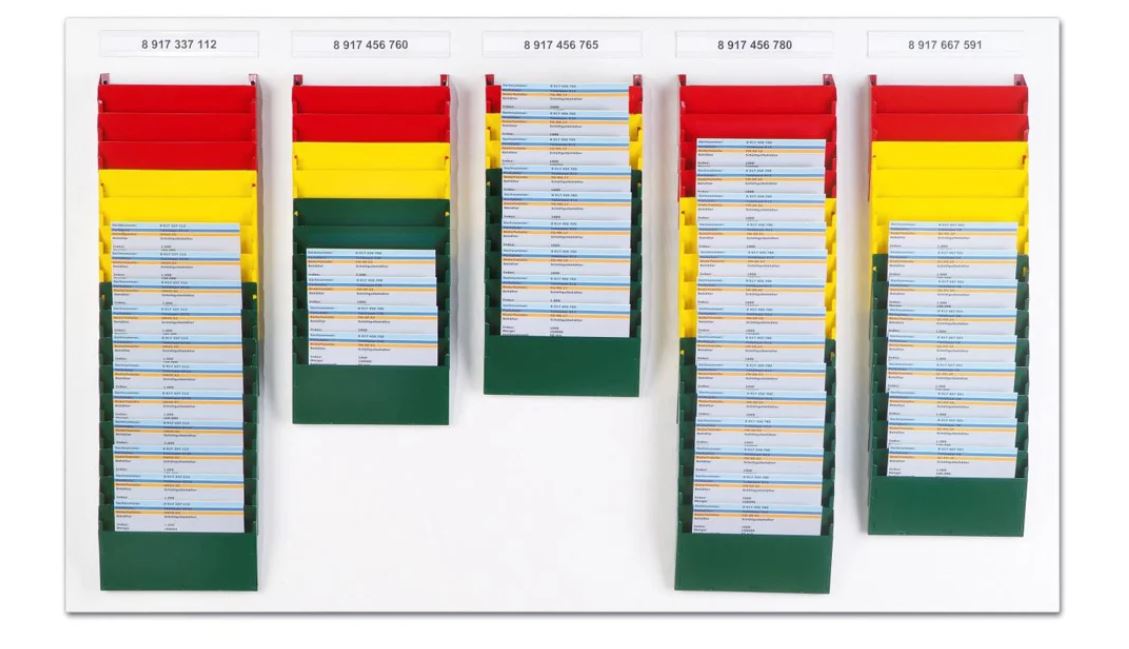

Kanban Board "Griffsicht"

- modular aus Metallfächern aufgebaut

- individuell erweiterbar

- individuelle Farbgebung möglich

- robust, ideal für Produktion & Fertigung

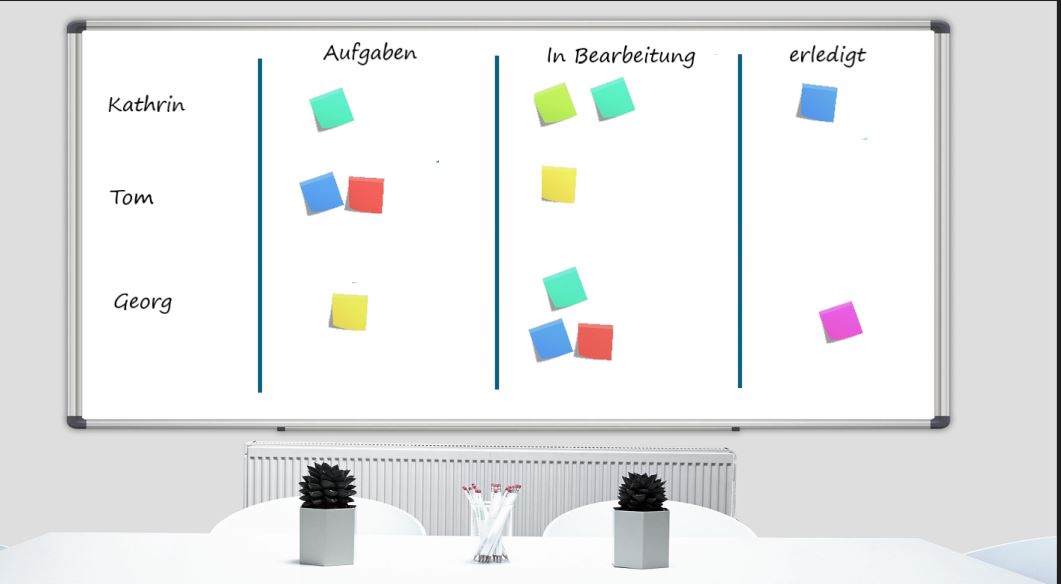

Einfache Kanban Tafel für das Büro

- Whitebord nach Wahl

- Beschriftung mit Markern

- Abtrennungen durch Magnetbänder

- umfangreiches Zubehör

Kanban Tafel gestalten - Sprechen Sie mit uns!

Die Bedürfnisse an eine Kanban Tafel sind nach Team, Abteilung und Unternehmen unterschiedlich und können oft mit Standardlösungen nicht optimal umgesetzt werden. Daher fertigen wir in unserer Tafelmanufaktur die Kanban Boards so, dass Sie zu Ihnen und Ihren Bedürfnissen passen. Gerne auch in Ihrem ganz speziellen Corporate Design und individuellem Druck. Denn was nicht passt, wir passend gemacht! Greifen Sie gleich zum Telefon und rufen Sie uns an.

Aufbau einer einfachen Kanban Boards - so geht´s

Das Kanban-Board ist so aufgebaut, dass es nicht nur alle in einem Projekt zu erledigenden Aufgaben für alle transparent anzeigt, sondern auch den Arbeitsfortschritt jeder einzelnen Aufgabe. Dafür werden zunächst Spalten angelegt. Diese stehen für die einzelnen Arbeitsschritte, die eine Aufgabe durchläuft. In diesen Spalten werden Karten platziert, auf die jeweils eine zu erledigende Aufgabe geschrieben wird. Im Verlauf des Arbeitsprozesses werden die Karten von der ersten bis zur letzten Spalte verschoben, bis die Aufgabe erledigt ist. Dank dieser sehr reduzierten Darstellung kann jeder sofort den Status quo des Projekts oder einer einzelnen Aufgabe erkennen.

Whiteboard "CurveLine"

- Grundlage für Kanban Board

- magnethaftend & beschreibar

Die Kanban Tafel, ein Gewinn für Team & Unternehmen

Gerade mittelständische Unternehmen haben erkannt, dass nicht nur variantenarme Fertigungen von einer Kanban-Steuerung profitieren. Mit den richtigen Hilfsmitteln lassen sich Produktivitäts- und Geschwindigkeitsvorteile auch bei einer größeren Variantenzahl erfolgreich realisieren. Zentrales Organisationsmittel ist dabei die Kanban Tafel. Sie bietet den Planern und Mitarbeitern gleichermaßen die Möglichkeit, einen umfassenden Überblick über Bedarf und Vorräte zu gewinnen und ihre Arbeitsabläufe im Team selbst zu steuern.

Die Kanban-Tafel ist ein unschätzbares Instrument, das den Mitarbeitern hilft, sich am Arbeitsplatz zurechtzufinden und ihre Aufgaben besser zu verwalten. Es verschafft ihnen einen Überblick darüber, wer an was arbeitet, welche Aufgaben abgeschlossen sind und welche Projekte ihre Aufmerksamkeit erfordern. Durch diese Transparenz der Arbeitsabläufe und des Fortschritts können Teams besser zusammenarbeiten und sich auf ihre Ziele konzentrieren. Auch auf sich ändernde Arbeitsbelastungen kann man so schnell reagieren, was dazu beiträgt, dass alle Beteiligten informiert und produktiv bleiben. Insgesamt bietet die Kanban-Tafel ein effizientes System, mit dem Teams effektiv planen, Prioritäten setzen und Arbeitsaufgaben verfolgen können, während alle Beteiligten auf dem gleichen Stand bleiben.(Bildquelle Freepik)

Die Arbeit mit dem Kanban Board zeigt Wirkung:

- Zeitersparnis - offenen Aufgaben sind für jeden sofort ersichtlich & unnötige Meetings fallen weg.

- Die Zusammenarbeit im Team wird gestärkt

-

Transparenz - jeder im Team, ist über den Status Quo im Bilde

- Verbesserung der Arbeitsergebnisse - durch ständige Anpassung und flüssigere Arbeitsabläufe

- Steigerung der Motivation und Zufriedenheit im Team

Sie möchten Beratung zur Kanban Tafel?

Dann nehmen Sie doch gleich Kontakt mit uns auf, wir stehen Ihnen mit Rat und Tat gerne zur Seite !

Sie erreichen uns unter Tel. +49 (0)9531 61-222 oder nutzen Sie unser Kontaktformular.

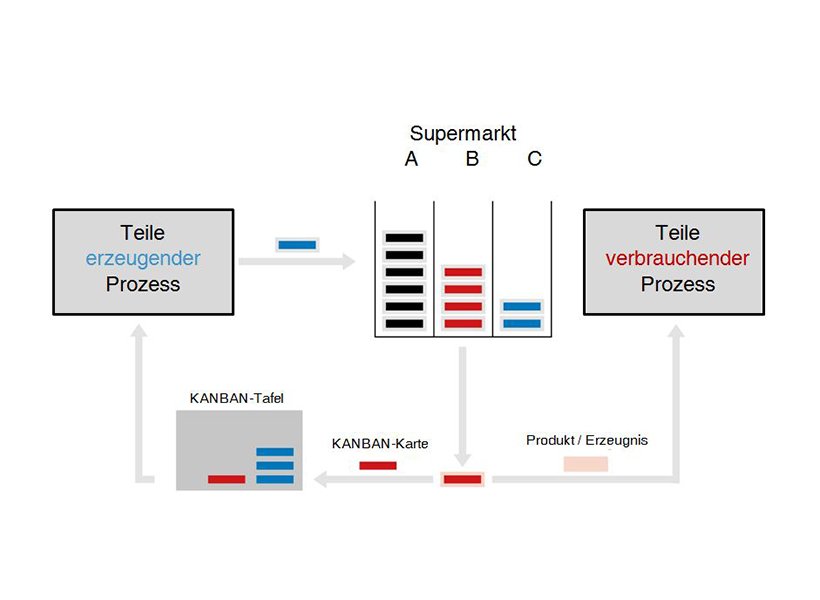

What is a Kanban System?

The Kanban system reduces current stocks and finished goods. This reduces capital commitment and inventory-caused waste. Stocks are limited, so that it is not possible to exceed the set stock level, flexibility towards fluctuating customer requirements is increased, production control is drastically simplified. The Kanban system is also often referred to as the supermarket principle: A consumer takes pre-produced goods from a shelf. The supermarket operator refills the removed quantities. This means for the production: Planning interventions are only necessary with regard to the quantity to be stocked and the time of ordering. This reduces planning and control activities in daily operations to a minimum. The processes are linked via a buffer store, in which the supplier provides the produced parts and from which the customer takes the parts. Kanban thus replaces conventional order control with consumption control by creating a linked, self-controlling control loop from two consecutive processes. The control loop consists of a process that consumes parts, the customer, and an upstream process that produces parts, the supplier. The kanban card serves as an order document. Depending on the specific requirements, different types of Kanban are used: traffic light Kanban, container Kanban, double circuit Kanban.

Through Kanban Board more personal responsibility & improved communication in the team

"A great advantage of the Kanban Board is the necessity of communication within the team, i.e. between departments and between employees themselves. The shift managers hold their meetings daily in front of the Kanban Board. The introduction of this system has also successfully strengthened the personal responsibility of the leading employees. We can now generally rely on a seamless flow of information across departments".

Gerhard Hintsteiner, Production Planning, Georg Fischer GmbH & Co. KG in Altenmarkt